Navigating the Amazon marketplace is challenging. Success as a brand owner requires aligning multiple elements: product demand, quality, content, organic visibility, traffic, and competition. Excelling in these areas is vital, but there’s one foundational element that often goes overlooked—inventory.

Without sufficient inventory to meet demand, even the best product pages and advertising strategies fall short, leading to lost sales, disappointed customers, and a weakened brand reputation. As of April 2024, Amazon has added another layer to this challenge, charging FBA sellers extra fees for low inventory levels. This means that, beyond the risks of lost sales and diminished rankings, low inventory now impacts your costs directly.

It’s a lose-lose situation—you miss sales, accrue additional costs, and lose customer loyalty. Meanwhile, your competitors benefit, capturing the sales you couldn’t fulfill.

Effective inventory management isn’t just a strategy; it’s essential to retail success. With ecommerce supply chains still evolving in areas like predictive planning, restocking schedules, and rapid inventory transfers, brands must be proactive. Amazon sellers who plan ahead, monitor inventory closely, and replenish efficiently will gain a competitive edge.

This article will dive into the risks of low inventory for Amazon sellers and offer actionable strategies to keep your inventory levels steady.

Risks of Low Inventory for Amazon Sellers

Maintaining sufficient inventory is vital for Amazon sellers to meet customer demand, ensure fast shipping, and prevent sales disruptions. Low inventory poses significant risks for Amazon sellers, impacting sales, rankings, and ad efficiency.

When inventory levels dwindle, sellers risk stockouts, leading to missed revenue and potential declines in Amazon’s organic rankings. Amazon’s algorithm favors products with consistent availability, meaning low inventory can lower search visibility and reduce Buy Box eligibility.

Here are the key risks of low inventory for Amazon sellers:

1. Lost sales

The most immediate impact of low inventory is lost sales. When a product is out of stock, brands may lose sales to third-party sellers. According to Profitero, a market intelligence tool, low inventory can lead to a 42% loss in sales when the in-stock rate drops from 90% to less than 30%. With all the impact that low stock and out-of-stock instances cause on your products, it takes 4 days to regain full sales volumes after being out of stock for 1 day.

2. Organic visibility

Amazon prioritizes products with high availability and conversion rates at the top of search results. Running out of stock or maintaining low inventory not only risks sales but also causes a drop in organic rankings, often lasting beyond the out-of-stock period. Building search rank on Amazon takes time, and losing rank due to low inventory costs both time and sales.

3. Cost efficiencies

Low inventory levels reduce cost efficiency in two ways:

- Impact on PPC Effectiveness: If PPC campaigns continue for items that are nearly out of stock, clicks won’t convert into sales due to extended delivery timelines, resulting in inefficient budget use and higher advertising costs.

- Additional Low Inventory Fee from Amazon: Recently, Amazon introduced a low inventory fee for sellers. US Sellers with less than 28 days of inventory (calculated with the last 30 days of sales Daily run rate) will incur an additional Low Inventory fee. These fees add unnecessary costs to your bottom line.

Over time, a history of low inventory levels and stockouts may make it difficult for sellers to regain competitive standing, affecting long-term growth. By closely monitoring inventory, sellers can mitigate these risks, maintaining sales momentum and customer satisfaction.

How to Mitigate Low and No Inventory Issues

Here are three effective strategies to address low or no inventory issues:

1. Better Demand Planning

Accurate demand forecasting is essential for maintaining optimal stock levels. By analyzing sales trends, seasonality, and competitor activity, brands can anticipate demand and better manage inventory.

Here are a few ways to do this effectively:

- Use Carbon6 Free Inventory Planner to plan inventory better: prevent stockouts.

- Use Reporting tools: Use demand planning tools to ensure that you are reminded or alerted of low or no inventory instances on time. You can use tools like SoStocked or D8aDriven.

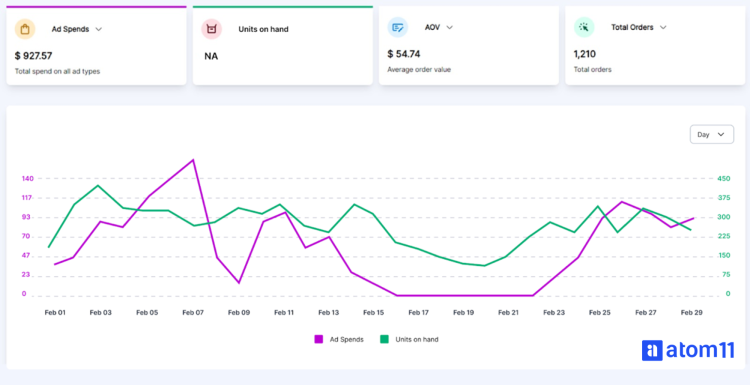

- Use Retail-aware advertising tools: Retail-aware Amazon PPC tools bring together advertising data like ad spend, ACOS, TACOS with Seller Central data like inventory, pricing, and competitors. In one dashboard, you can track these data points manually and set up alerts for them.

2. Pricing Control

Many sellers increase prices when their inventory is low. This leads to a temporary reduction in sales velocity and helps in preventing out of stock instances. Pricing control is a great strategy if dealing with a smaller number of ASINs. Once you have increased prices to curb out-of-stock, you will need to remember to reset the pricing when ASIN is back in stock.

3. Inventory-Aware Advertising

Inventory-minded marketing or Inventory-aware Ads is a concept in which marketing (Amazon PPC) and inventory team talk to each other. Inventory-aware ads automatically pause when stock is low and ramp up when inventory is high.

Since inventory numbers change fast for ASINs and there are multiple ASINs to take care of (sometimes running in thousands), it is usually important to automate this step.

Retail-aware PPC software like atom11 not only provides sales velocity data (daily run rate) on an ASIN level but also helps in automating actions on ads with inventory.

Watch this short video for a step-by-step demo.

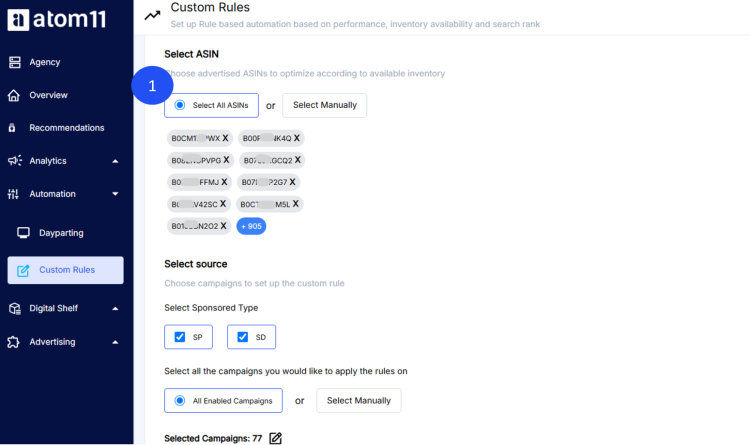

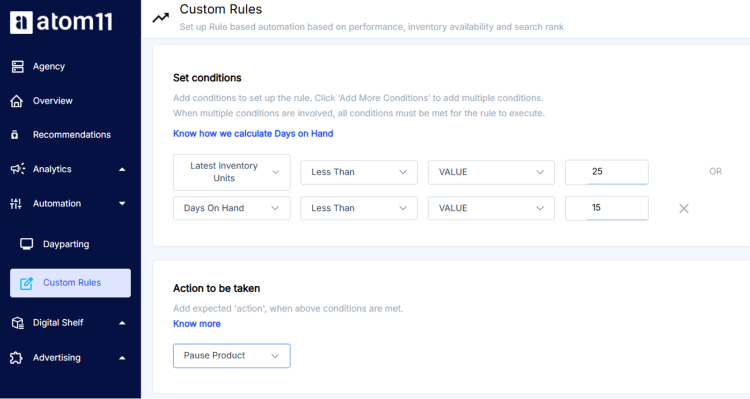

For example, in the below screenshot, you can set up an automation in 3 simple steps:

Step 1: Select ASINs to set up automation (or copy-paste a list)

Step 2: Define condition – ex. If inventory units < 50 OR if Days on hand < 15 days

Step 3: Define action – ex. Pause Product ad.

The automation will not only pause the product ad when the above condition is met but also automatically unpause ads when the condition stops being true (i.e. when inventory units increase or are back in full volume).

This simple automation helps you tons:

- Saves inventory from going out of stock as you reduce sales velocity at the right time

- Makes ad spend more efficient – spending on ads when inventory is low not only adds to wasted spend but also leads to increased ACOS (as customers may not buy with high delivery timelines)

- Saves time as you do not have to do the above steps (for every single ASIN) manually.

Take Control of Your Amazon Inventory and Ads

Maintaining the right balance between inventory levels and ad spend helps avoid unnecessary costs and maximize your Amazon performance. Tools like atom11’s retail-aware advertising features allow you to manage ad spend efficiently, focusing promotions on items with adequate stock and pausing ads for those running low.

Accurate forecasting also makes a big difference. Tools like SoStocked for demand planning help you not only avoid costly stockouts but also predict upcoming overstock fees. Together, these tools help you keep inventory steady, maintain customer satisfaction, and keep sales on track.

Combining demand forecasting, pricing adjustments, and inventory-aware advertising means you’re taking a smarter approach to managing your Amazon business. With the right tools, you pocket more profit or reinvest into growth.