Quarter-end chaos is upon us, and you’re probably feeling anxious about having to navigate the busiest season of the year amid slowing online sales growth, economic uncertainty, and concerns about a looming recession.

While these headwinds are out of your control, have no fear: There are still some strong tailwinds on the horizon that support business growth, such as the October Prime Early Access Sale, Black Friday/Cyber Monday (BFCM), the pre-Christmas rush, and year-end sales.

If you’re worried about having poor Amazon inventory turnover as you near the end of the year, you can rest a little easier. Insider Intelligence predicts that Amazon will continue to be the go-to shopping platform for customers, accounting for 37.8% of all US ecommerce sales in 2022.

What should you do to make sure some of these sales come through your Amazon shop?

Two things: Capitalize on end-of-year opportunities and mitigate threats like overstocking or running out of stock altogether.

Easier said than done, right? Maybe not.

What Is Amazon Inventory Turnover?

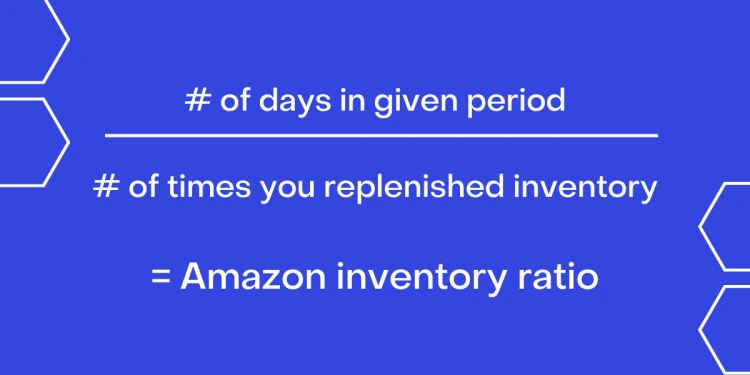

Amazon inventory turnover represents the rate at which you sell and replenish inventory during a particular period. The formula is pretty simple:

For example, if you replenished your inventory eight times in 365 days, you’d be turning over inventory every 46 days.

Retailers and ecommerce sellers usually compute their turnover ratio based on a yearly period. The ideal number of turns per year, however, varies by retail sector. For retail giants like Amazon, for example, 15 turns per year might be too many and likely indicates that they’re stocking out too often. That same amount might be too low for fresh grocery stores that typically need to sell perishable goods as quickly as possible.

As a general benchmark, though, a good Amazon inventory ratio for sellers is between five and 10, which means you’re selling and restocking inventory every one to two months. A solid turnover rate like this underscores your efficiency in managing your Amazon business.

To help you maintain a healthy inventory turnover rate in Q4 and beyond, follow these eight best practices.

1. Fine-Tune Your Forecasts

Inventory forecasting, the process of calculating how much to order to maintain healthy inventory levels, is one of the most crucial aspects of managing an Amazon business. And it doesn’t have to be super complicated.

What’s the secret to successful forecasting?

Taking a close look at your data. The data can help you decide what to include or exclude from your forecasts to generate the most accurate projections possible. Ideally, you should forecast inventory needs based on historical sales data, along with anticipated demand, stockouts, sales spikes, and future marketing plans. Taking all of these into account is known as forecast modeling.

Here’s an example:

Suppose you stocked out and wanted to know how much to reorder. If you exclude the days you ran out of stock from your forecast, you’ll increase your averages and get a higher prediction than your previous forecast, which will help you avoid under-ordering again.

Another smart inventory forecasting technique is factoring out non-recurring sales spikes to prevent over-ordering. This is especially true for fads or items featured on holiday gifting news segments that are popular for a time, but quickly fall out of trend. You simply don’t want to get stuck with a surplus of slow-moving products — that’s only going to cost you in holding fees, such as storage costs, inventory write-offs, insurance, warehouse labor fees, and more.

2. Set Aside Some Buffer Stock

Buffer stock is the extra inventory you save for a rainy day. Q4 is notorious not only for fierce competition, but also for warehouse constraints and shipping delays due to a sharp uptick in package volumes.

So, it would be wise to keep some buffer stock in your third-party logistics (3PLs) and transfer additional units as needed to stay in stock through these challenges. A good rule of thumb for private label sellers on Amazon is keeping at least a 30 to 45 day buffer. Don’t wait for your buffer inventory to reach zero before reordering. Instead, you should plan to transfer with enough time for your inventory to arrive before you start eating into your buffer stock.

Here are some best practices to consider:

- Set a reorder point but adding your days of buffer stock to your days of lead time to understand how far in advance you need to place your order for on-time arrival.

- Enable stock availability alerts to stay on top of inventory levels.

- Account for potential Fulfillment by Amazon (FBA) check-in delays.

- Discuss supply chain strategies with your logistics partner.

With every supply chain strategy comes pros and cons, so weigh your options carefully. For instance, Small Parcel Deliveries (SPDs) usually get checked-in faster than Less Than Truckload (LTL) shipments, but they tend to be more expensive.

3. Automate Repetitive Processes

Calm Q4 chaos by automating repetitive processes like ordering, inventory tracking, and inventory forecasting.

To efficiently manage your products, use an FBA inventory spreadsheet template (ideal for stores with fewer than five products) or inventory management software (for stores with multiple products and marketplaces).

If you’re an advanced seller, consider implementing the min-max restocking method to streamline the reordering process for each of your products. The minimum value represents the point at which you reorder, while the maximum value is the highest unit quantity you don’t want to exceed to maintain an optimal inventory turnover ratio. To get your ideal order size, subtract the minimum from the maximum.

When your inventory reaches its reorder point, you’ll know when to send a purchase order (PO) to your supplier or a work order (WO) to your 3PL explaining how you want them to handle your existing inventory — such as shipping to an FBA center or bundling multiple items into a single unit.

Ordering or transferring inventory too late can also cause stockouts, which is bad for your inventory turnover ratio. You can invest in inventory management software with a built-in PO/WO system to:

- Standardize your PO/WO template for each product. You no longer have to create a brand new PO every time you order. A PO automation tool will auto-populate your template with order details.

- Eliminate or reduce manual processes, such as placing orders via email, text, or phone call.

- Assign a default lead time to each of your POs to help you figure out the best shipping schedules and deadlines.

Once you’ve streamlined your management software, you can then train an Amazon virtual assistant to handle these tasks for you, allowing you to focus on other essential parts of your business.

4. Adopt Inventory-Minded Marketing

What’s the Inventory-Minded Marketing concept?

It’s the idea that when your inventory and marketing teams don’t communicate with each other, problems arise.

Imagine your marketing team running an aggressive ad campaign that brings in a ton of business. What’s the issue? You run out of stock.

The trick to avoiding this kind of situation is to have your inventory team vet marketing plans before starting any campaign. This will help you ensure there’s enough supply to meet the anticipated demand.

In order to facilitate seamless coordination between those two teams, you need to establish vital touch points. You might consider using inventory reporting tools, for example, which you can use to monitor your store’s inventory health. Using these tools, the inventory manager can provide the marketing manager with a stockout risk report to let them know which products are at risk of stocking out soon. From there, the marketing manager can make the necessary adjustments to prevent that from happening.

Other reports that the inventory team can send to the marketing team include:

- Slow sellers report, which identifies slow sellers and helps you determine how you might be able to revive them into being more viable, successful sellers. This report would use a minimum and a maximum sales velocity.

- Liquidation report, which tracks extremely slow sellers you no longer want to restock so you can immediately move them before they start incurring holding costs. This would require a minimum sales velocity threshold below that of those on the slow sellers list.

- Overstock report, which shows the number of days a product has been left sitting in FBA. Anything over 90 days of supply should quickly be sold through to avoid excess fees. This is particularly important considering that Amazon now charges an aging inventory surcharge on items that have been unsold for 271 to 365 days. That’s on top of your monthly storage fees and other applicable fees. With that in mind, you’ll want to create a plan to eliminate stale goods more quickly.

5. Update Listings and Optimize Pay-Per-Click Ads

Q4 is the best time to rake in sales — so expect fierce competition.

The best ways to stand out?

- Update your listings with relevant holiday-themed photos and keyword-rich product descriptions. It’s also crucial to convert your old HTML tags on your descriptions to the new format to ensure your copy will appear with the most up-to-date formatting.

- Launch ad campaigns to reach more customers and optimize each ad for maximum conversion.

- Get your promos out to market early to increase your product’s sales ranks before everyone else does.

Ensuring you have the most up-to-date, accurate, and compelling copy can be a boon to your sales efforts during peak seasons.

6. Move Excess Inventory and Slow Sellers

Improve your Amazon inventory turnover rate and minimize holding costs by converting excess units and slow sellers into sales.

How?

- Bundle slow sellers with your top sellers to encourage shoppers to buy more products.

- Offer deep discounts via Amazon Outlet or Lightning Deals. A good post-holiday buying period strategy is to run a flash sale or participate in Amazon’s discount deals to get rid of excess stock and attract new customers, like those who are eager to buy items at a year-end discount that they didn’t get as gifts.

- Sell leftover inventory through other eCommerce platforms and fulfill orders via Amazon Multi-Channel Fulfillment (MCF). Amazon will still count your MCF sales toward your sales velocity, which can help improve your overall Inventory Performance Index score, the ratings system Amazon uses to rate how good you are at inventory management.

- Liquidate inventory that’s no longer worth your time and effort to recover some capital and reduce costs associated with keeping unprofitable products at FBA, such as long-term storage fees and aged inventory surcharges.

7. Leverage Your Connections With Suppliers and 3PLs

Increase your bottom line by working with your suppliers and 3PLs to lower costs. When you have extra money to spend on ads, for example, you have more opportunities to turn inventory into cash.

A few key strategies include:

- Negotiating for a better lead time to avoid costly delays.

- Discussing flexible payment terms for better cash flow. You might negotiate a payment schedule where you pay 25% upfront for 30,000 units, for example. Then, your vendor ships out 10,000 units at a time, but you only pay 75% for each batch upon its arrival.

- Asking for better incentive tiers, discounts, or rebates for ordering raw materials in advance, especially if procuring raw goods is taking longer than expected.

- Auditing invoices to check for duplicate charges.

- Reviewing your 3PL’s fee structure. You might be surprised to find that you can save some money by restructuring your warehouse labor costs. Examine how your warehouses calculate labor costs: If they charge $50 per hour, for example, but it only takes them 15 minutes to ship your boxes, are they charging you for the full hour, or breaking costs down into 15-minute increments?

It can be beneficial to try to lower shipping and storage costs by leveraging your existing connection with your logistics provider or supplier. A reputable provider is always looking to work with sellers who value lasting partnerships, and most are willing to make improvements to ensure everything goes smoothly. Remember, your success is their success, too.

8. Don’t Put All Your Eggs in One Basket

If the 2021 Suez Canal fiasco had anything to teach us, it would be to not put all your shipments on one boat. Otherwise, when it gets stuck halfway around the world, you’ll end up without your much-needed inventory for weeks, increasing your risk of stocking out. The same is true for when Amazon skips over your trailer or loses your inventory and it ends up not getting checked-in on schedule.

To stay flexible during supply chain troubles, consider splitting your shipments. Ship the majority of your inventory by boat, for example, and reserve about a month or two with your supplier to send by air if your cargo gets stuck at port. You’ll sleep peacefully at night knowing all your bases are covered in the event your container gets held up in a traffic jam in one of the world’s busiest shipping routes.

Here are some other smart strategies to manage Amazon logistics:

- Hire a 3PL company as a backup warehouse. You don’t want to depend on Amazon for all of your distribution and storage needs because they can be unreliable sometimes. Use a 3PL as backup, specifically for storing your buffer inventory so that you’ll have some units available for small parcel shipping in case of emergency. This option may be more expensive than Amazon, but it can be a lifesaver when you need your inventory in a pinch.

- Hold some inventory back at your supplier. This is another contingency plan that might save you in the event of extremely long shipping delays. If you absolutely need to, ship your reserve stock by air.

- Use a hybrid fulfillment system. Going hybrid can be an effective way to overcome FBA inventory restrictions and check-in delays. You can easily switch to a Fulfillment by Merchant (FBM) approach once you max out your storage limits or if Amazon is running behind in receiving your shipments.

Increase Efficiency to Improve Your Amazon Inventory Ratio

Stocking out and overstocking are part of every seller’s Amazon journey. The best way to minimize these headaches is by increasing your inventory management efficiency with the help of automation tools and these eight best practices.

It’s only when inventory threats are kept at bay that you can start seeing significant improvements in your Amazon inventory turn ratio.

Want to transform your Amazon business into a well-oiled machine that runs itself? Use SoStocked and spend less time managing the daily demands of inventory management — and more time on growing your brand.

Want more content like this? Check out our recorded webinar, 3 Silent Amazon Profit Killers.